MOQ: | 4KM | Packaging: | Wooden drum |

Delivery Time: | 7-15 working days | Brand Name: | SOCT |

Supply Ability: | 5000KM/month | Model Number: | GYTC8A |

Place of Origin: | Jiangsu,China | Certification: | ISO9001,ROHS,CE,FCC SDOC |

Detail Information:

Fiber Count: | 2-144 |

Fiber Type: | G652D,G655D,OM1,OM2 |

Fiber Brand: | YOFC,HTGD |

OEM: | Yes |

Application: | Aerial installations |

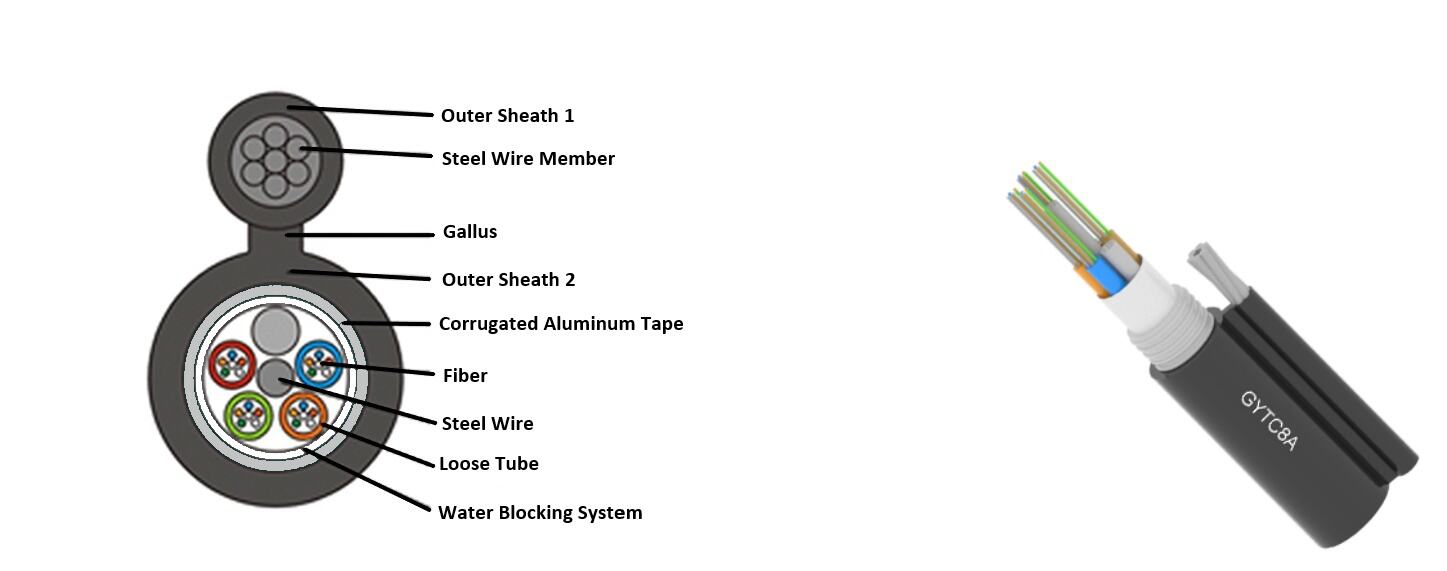

Structure | Figure 8 |

Messenger Wire | Steel wire*7 |

Armored | Corrugated Aluminium Tape |

Central strength member | Steel Wire |

Features:

· Self-Supporting Structure: GYTC8A cables are designed with a figure-eight shape and internal steel wires that provide excellent tensile strength, allowing the cable to be self-supporting without requiring additional support structures. This significantly simplifies installation and reduces costs.

· Rodent and water Resistance: The optical fibers are enclosed in loose tubes filled with a waterproof compound and wrapped with a water-blocking tape. The outer layer of an aluminum polyethylene laminate (APL) further enhances the cable's resistance to water ingress and makes it resistant to damage from rodents, ensuring long-term stable operation of the optical fibers.

· Superior Tensile Strength: The steel wires within the cable contribute to its high tensile strength, enabling it to withstand significant pulling forces. This makes GYTC8A cables suitable for installation in various complex terrains and environments.

· Strong Corrosion Resistance: The cable's outer sheath is made of weather-resistant and corrosion-resistant polyethylene material, capable of withstanding various harsh environmental conditions and extending the cable's service life.

· Easy Installation: GYTC8A cables are lightweight and flexible, making them easy and quick to install. They can be easily deployed for both aerial and direct burial applications.

Technical parameters:

No. of cable | 4 | 8 | 12 | 24 | 48 | |||||

Fiber Model | G.652D | |||||||||

Design(Strength Member+Tube&Filler) | 1+5 | 1+5 | 1+5 | 1+5 | 1+5 | |||||

Central Strength Member | Material | Steel Wire | ||||||||

Diameter(±0.05)mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |||||

Loose Tube | Material | PBT | ||||||||

Diameter(±0.06)mm | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | |||||

Thickness(±0.03)mm | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | |||||

The Max.Core NO./Tube | 4 | 4 | 6 | 6 | 12 | |||||

Filler Rope | Material | PP | ||||||||

Diameter(±0.06)mm | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | |||||

NO. | 4 | 3 | 3 | 1 | 1 | |||||

Water Blocking layer(Material) | Flooding Compound | |||||||||

Armoring | Material | Corrugated Aluminium Tape | ||||||||

Thickness(±0.05)mm | 0.25 | |||||||||

Support pieces | Material | Galvanized steel strand | ||||||||

Size(±0.1mm) | 2.7(0.9×7) | |||||||||

Web | Material | MDPE | ||||||||

Size(±0.2)mm | 2.0×2.0 | |||||||||

Outer Sheath① | Material | MDPE | ||||||||

Thickness(±0.2)mm | 1.2 | |||||||||

Outer Sheath② | Material | MDPE | ||||||||

Thickness(±0.1)mm | 1.6 | |||||||||

Cable Diameter(W×H)(±0.2)mm | 9.4*16.0 | 9.8*16.4 | ||||||||

Cable Weight(±10)kg | 150 | 158 | ||||||||

Min. bending radius | Without Tension | 10.0×Cable-φ | ||||||||

Under Maximum Tension | 20.0×Cable-φ | |||||||||

Temperature range (℃) | Installation | -20~+60 | ||||||||

Transport&Storage | -40~+70 | |||||||||

Operation | -40~+70 | |||||||||

Allowable Tensile Strength | Short Term | 2700N | ||||||||

Long Term | 1000 N | |||||||||

Allowable Crush Resistance | Short Term | 1500 (/100mm) | ||||||||

Long Term | 600 (/100mm) | |||||||||

G652D Fiber Data Sheet :

FIBER PERFORMANCE (ITU-G.652) | Item | specifications | |

Mode field diameter(μm) | 1310nm 9.2±0.4 | ||

1550nm 10.5±0.4 | |||

Coating diameter(μm) | 245±7 | ||

Coating non-circularity (%) | <6.0 | ||

Mode field /cladding concentricity error (μm) | ≤0.6 | ||

Cladding diameter(μm) | 125.0±1 | ||

Cladding non-circularity (%) | <1.0 | ||

Attenuation(dB/Km) | 1310mm ≤0.36 | ||

1550nm ≤0.22 | |||

1625nm ≤0.24 | |||

Cut-off wavelength (nm) | 2m(λc) 1150~1330 | ||

20m cable +2m fiber (λcc) <1260 | |||

Dispersion | Zero dispersion wavelength(m) 1300~1322 | ||

Zero dispersion slope(ps/nm2.Km) ≤0.092 | |||

Chromatic dispersion (Ps/nm2.Km) | 1285~1330nm ≤3.1 | ||

1550nm ≤18 | |||

1625nm ≤22 | |||

| Fiber color | blue, orange, green, brown, slate, white, red, black, yellow, violet, pink and aqua | |

Fiber Colors:

NO. | 1 | 2 | 3 | 4 | 5 | 6 |

Color | Blue | Orange | Green | Brown | Gray | White |

NO. | 7 | 8 | 9 | 10 | 11 | 12 |

Color | Red | Black | Yellow | Violet | Pink | Aqua |

Production workshop:

Quality verification:

Packaging:

FAQ:

Q1: How to choose the right optical cable?

Choosing an optical cable requires considering factors such as transmission distance, data rate, environmental conditions, and connection methods. You can provide your specific requirements, and our professional technical team will recommend the suitable optical cable Products for you.

Q2: What’s the MOQ?

The MOQ of Fiber Optic Cable depends on the product model and customer needs. You can consult our sales personnel for more details.

Q3: What’s delivery time?

Our delivery time is generally 7-15 working days. The specific delivery time will be determined based on the order quantity and production schedule.

Q4: Why are optical cable prices on the market so varied?

The price differences in optical cables are the result of multiple factors. When choosing optical cables, you should consider price, quality, brand, and after-sales service comprehensively to select products that meet your needs.

Q5: Is it possible to customize optical cables with special specifications?

Absolutely! We will have detailed discussions with you to understand your needs. Then, our engineers will design the optimal Solution based on your requirements. We will produce samples for your testing and confirmation. Finally, we will arrange mass production according to your confirmation.

From start to finish, we ensure quality and care —smooth production, safe delivery!