Blog

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

Updated on January 29, 2026 — In the context of the global AI boom, the optical fiber market has witnessed an unexpected and sharp price surge since the end of

In the complex world of telecommunications, outdoor cables often get the spotlight for their ruggedness. But for building interiors—data centers, office risers, and campus LANs—the real workhorse is the indoor

In today’s hyper-connected world, reliable fiber optic infrastructure is the backbone of high-speed telecommunications, metropolitan networks, and data center interconnections. Outdoor deployments, particularly in duct environments, face unique challenges: moisture

In 2026, with the continued rollout of 5G/6G backhaul, data center interconnections, metro backbone expansions, and smart city projects, demand for high-capacity 288 core fiber optic cable remains strong. The

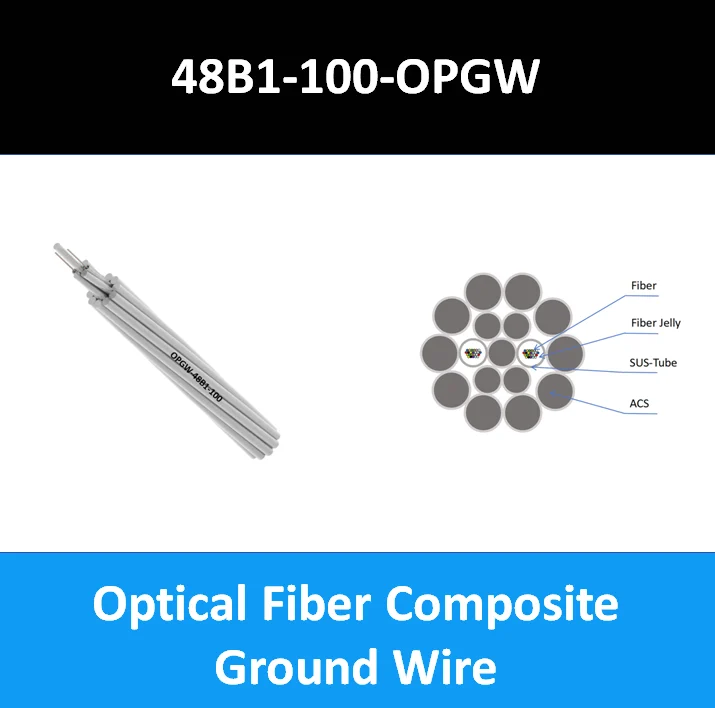

OPGW (Optical Fiber Composite Ground Wire) is a dual-functioning cable placed at the highest point of high-voltage transmission towers. The specific model OPGW-48B1-100 breaks down as follows: It combines the

Building a reliable aerial fiber network doesn’t always require the heavy-duty specifications of traditional ADSS cables. For internet service providers (ISPs) and telecom contractors working on last-mile connectivity or rural

Designing aerial fiber routes over long distances is never just about bandwidth. Span length, mechanical safety, installation efficiency, and long-term reliability all directly affect project cost and risk. For power

When you design an FTTH or FTTx network, the last segment from the distribution point to the subscriber is often the most fragile part of the entire link. It faces

When it comes to fiber-optic installations in demanding, industrial, outdoor or mission-critical environments—such as military, mining, oil & gas, underground, or remote-site connectivity—you need more than just a standard cable.

For many ISPs, system integrators and utility companies, the most economical way to extend fiber is still on existing poles. Aerial deployment avoids heavy civil work, shortens project schedules and