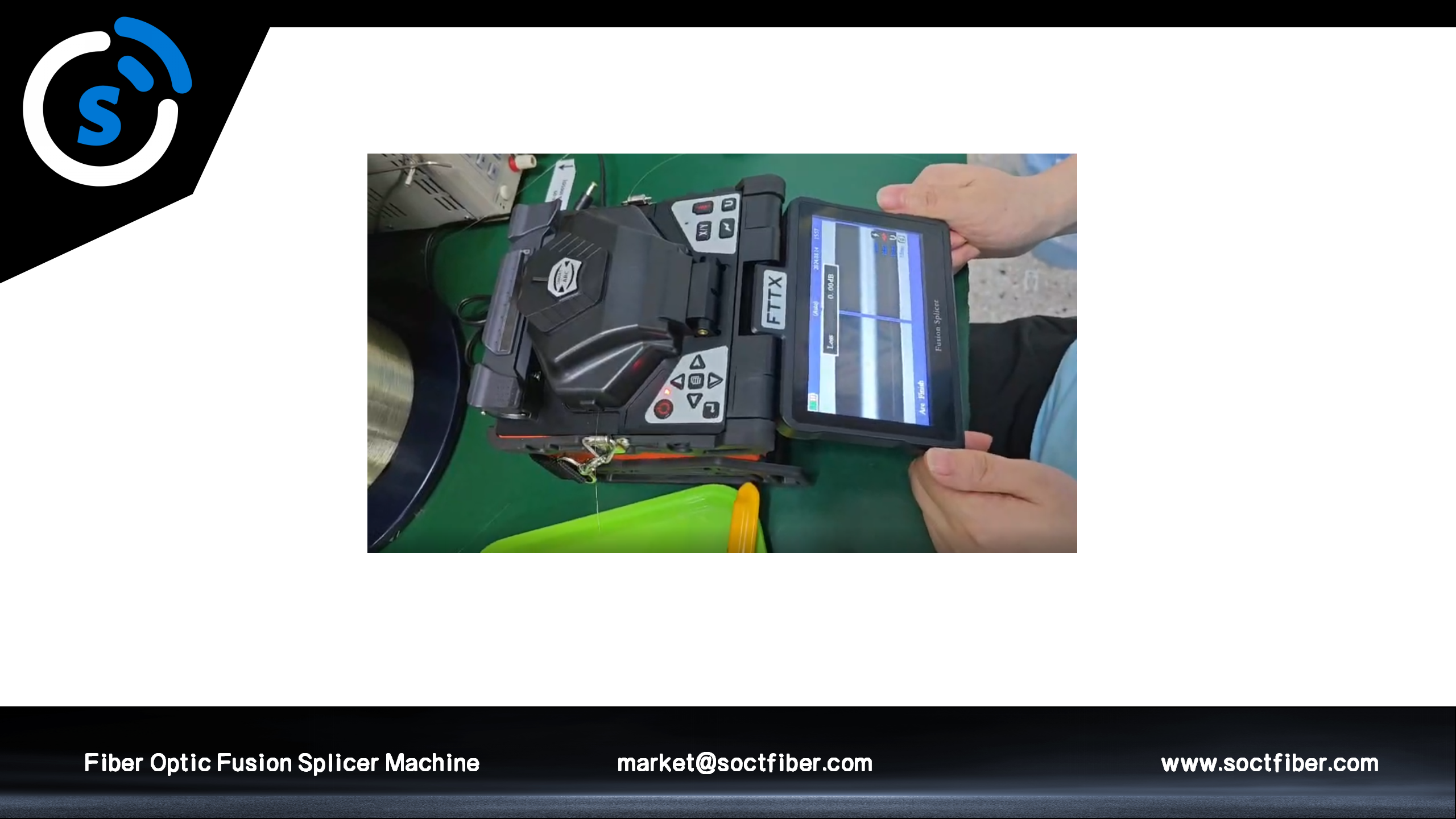

fusion splicer fiber optic

A fusion splicer is precision equipment used to connect fiber optic cables together. Here, their ends are melted and then held until they fuse into one. It is virtually impossible with the warmth from this that any signal loss at all will be amplified as well; on top of this, mechanical strain guarantees higher durability for joint connections. The main functions of a fusion splicer are fiber optic cables, both aligning and spliced together. This is heating the fibers at their connection points to form joins and then cooling them off and covering the joint. With advanced image processing, automated programs and high-precision motors, technological features like these now characterize reliable and consistent splicing every time. Fusion splicer applications are numerous, from telecommunications or data centers to cable television and medical equipment. In these fields reliable, efficient fiber connections prove essential.