Introduction

At the heart of modern communication networks, particularly in more challenging settings undersea or underground in mines are high-performance fiber optic cables. GYTA33, GYTA53 These two Cables are highlight because they were developed to an advanced level compared with our pears (one step beyond YD/T 901-2018 and IEC60794 strict). This ensures that the cables are dependable, robust and operate under optimal performance when transferring data across long distances amidst rugged conditions.

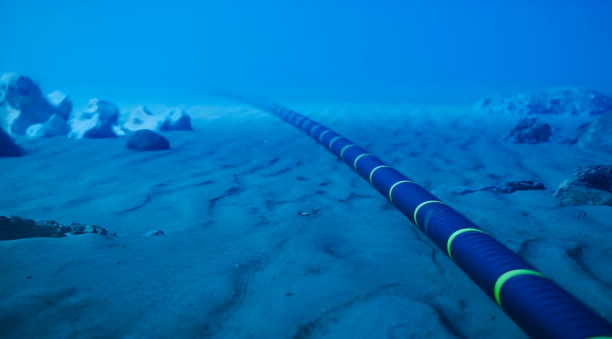

Deep: What You Should Know About Undersea Fiber Optic Cables

Undersea Fiber optic cables operate on the principle of total internal reflection to guide light signals along glass fibers in the cable. The US must have the cable laying effected by specialized vessels, which bury the cables underground to protect it from fishing gear and similar problems. To overcome this limitation, repeaters — which amplify the signal — are installed every few kilometers along the cable so that data can travel thousands of kilometers without degradation.

Underwater cables explained: Getting to know the infrastructure of GYTA33 and GYTA53 fiber optic cables

GYTA33 and GYSTA53 optical cables are intended for dissimilar but both equally challenging environments. The GYTA33 fibre cable is buried or submerged in water with a central bearing structure and sheathing of wet state polyethylene (PE) to protect against moisture ingress, prevent side-pressure and avoid mechanical damage. Used for long-distance dialing, local trunk lines and computer network systems.

Also, GYTA53 is a steel tape armored outdoor fiber optic cable suitable for direct burial. It has a loose tube made with around central FRP into inner PE sheath, longitudinal steel tape armor and outer black color HDPE jacket. It is very suitable for adapting to the environment and other mechanical behaviors, it has become one of our best-selling cables, particularly in high lightning or areas which are expose to higher level voltage.

Fostering Undersea Cables: Challenges in Deployment and Maintenance

There are many challenges when it comes to deploying and maintaining undersea cables. Problems include running of cables at the sea floor and reeling them back there, as well while precautions need to be taken using fibre optics in many environments due to their fragility. Underwater currents, earthquakes and corrosion (rust) can be environmental factors that increase the risk of accidents. Furthermore, cables are prone to physical damages caused by activities like fishing and anchoring. Ways to stop any harm from occurring are through safe-routing, designing the cables responsibly with extra protection and lobbying internationally for regulations that can prevent occurrences in protected areas where they go.

Implementation Standards: YD/T 901-2018 and IEC 60794-1

The YD/T 901-2018 standard specifies the requirements for communication use, layer-stranded filling-type outdoor optical cables, ensuring their performance, reliability, and consistency. It covers aspects such as optical fiber type,cable structure, allowable tension,and environmental performance.

IEC 60794-1, on the other hand, is an international standard that provides generic specifications for optical fiber cables. It outlines the geometrical, transmission, material, mechanical, ageing, climatic, and electrical properties of the cables. The standard ensures that the cables can withstand various environmental exposures and maintain their performance over time.

Fiber Optic Cable Deployment Challenges

While significant improvements have been made with the evolution of cable technology, fiber optic cables are notoriously difficult to install when space constraints and harsh conditions such as in deep sea or mining settings come into play:

The physical constrict of these environments is brutal, and cause wires to be broken that affects their working as well long lasting.

Specific Installation Requirements: To avoid damage, the fiber optic cables have to be installed using specialized equipment and skills which are expensive and complicated.

Tools and Talent: Substantial investments needed for specialized tools & equipment, trained manpower to lay cable.

Signal attenuation: This is the weakening of signal strength over a long distance, whereby we have to design and deploy signal amplification technology for high-frequency signals to ensure data transmission integrity.

In the face of these problems, for networks similar to passive FTTX using GYTA33 and GYTA53 cables defined in YD/T 901-2018 recommendatory or IEC60794-1 standards is worthful even with higher prices. These include navigation systems for telecommunications, mining and marine sectors providing high-accuracy real-time data transmission with the most enhanced network security.

Conclusion

Commonly known as YD/T 901-2018 and IEC60794-1, loose tube optic cable GYTA33 FIBER OPTIC CABLE AND GYTA53 Fiber Optic Cable are intended for use in long-distance communications in high mechanical resistance. These fibers have introduced a wrapper of fresh technology and this is why stand as the most preferred medium by many for continuous data transfer and stability in network, that are complicit with hard industry norms. Cables are a priority because of high-speed data transmission rates and packet volume technologies such as 5G in today's communication infrastructure. The GYTA33 and GYTA53 cables that are most suitable for achieving the necessary performance of communication networks are thus seen as a key element in further developing these networks.