Description:

The 96 Core Double Jacket Aerial ADSS Fiber Optic Cable is designed for aerial deployment with a 200m span. Featuring a double jacket construction, it offers enhanced protection against mechanical stress, environmental hazards, and UV exposure. The ADSS (Aerial Drop Self-Supporting) design allows for easy installation without the need for support wires. With 96 fibers, this cable supports high-capacity data transmission for backhaul, FTTH, and telecom network applications, ensuring low attenuation and high reliability over long distances. It is ideal for long-span aerial fiber optic networks.

MOQ: |

50KM |

Packaging: |

Wooden drum |

Delivery Time: |

5-25 days |

Length: |

3 KM/drum or Customization |

Brand : |

OEM |

Model Number: |

ADSS Fiber Optic Cable |

Place of Origin: |

Jiangsu,China |

Certification: |

ISO9001 |

Detail Information:

Fiber Count: |

96F |

Fiber Type: |

G652D,G655D,OM1,OM2 |

Fiber Brand: |

YOFC,HTGD |

Application: |

Aerial |

Span |

200m |

MAT |

3600N |

MAX Wind resistance |

25m/s wind speed + 0mm Ice Load |

Technical parameters:

Cable fiber count |

/ |

96 |

|

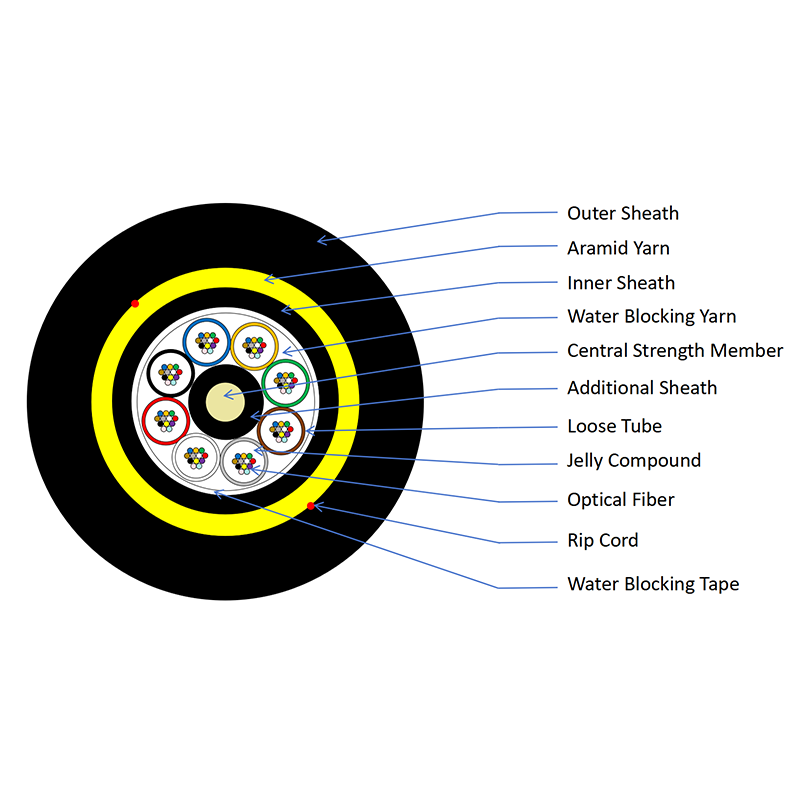

Structure |

/ |

1+8 |

|

Fiber style |

/ |

G.652D |

|

Central strength member |

material |

mm |

FRP |

Diameter(average) |

2.1 |

||

Loose Tube |

Material |

mm |

PBT |

Diameter(average) |

2.1 |

||

Thickness(average) |

0.35 |

||

Max fiber/loose tube |

12 |

||

Tubes color |

Full color identification |

||

Water resistance |

Material |

/ |

Cable jelly + water resistant layer |

Non-metallic strengthen components |

Material |

/ |

Aramid Yarn |

Inner sheath |

Material |

mm |

HDPE |

Thickness |

0.9 |

||

Outer sheath |

Material |

mm |

HDPE |

Thickness |

1.8 |

||

Cable diameter(average) |

mm |

14.1 |

|

Cable weight (Approximate) |

kg/km |

135 |

|

Attenuation coefficient(Max) |

1310nm |

dB/km |

≤0.35 |

1550nm |

≤0.21 |

||

Rated Tensile Strength(RTS) |

kn |

≥9.0 |

|

Max allowed tension( MAT) |

kn |

≥3.6 |

|

Wind velocity |

m/s |

25 |

|

Icing |

mm |

5 |

|

Span |

M |

200 |

|

Crush resistance |

Long term |

N/100mm |

≥1100 |

Short term |

≥2200 |

||

Permission Bent Radius |

static |

mm |

15D |

dynamic |

20D |

||

Temperature |

When laying |

℃ |

-20~+60 |

Storage and transportation |

-40~+70 |

||

running |

-40~+70 |

||

Scope of application |

Suitable for voltage level under 110kV, wind speed below 25m/s, icing 5mm |

||

Cable Marks |

Printing according to customer's requirements |

||

G652D Fiber Data Sheet :

FIBER PERFORMANCE |

Item |

specifications |

|

Mode field diameter(μm) |

1310nm 9.2±0.4 |

||

1550nm 10.5±0.4 | |||

Coating diameter(μm) |

245±7 |

||

Coating non-circularity (%) |

<6.0 |

||

Mode field /cladding concentricity error (μm) |

≤0.6 |

||

Cladding diameter(μm) |

125.0±1 |

||

Cladding non-circularity (%) |

<1.0 |

||

Attenuation(dB/Km) |

1310mm ≤0.36 |

||

1550nm ≤0.22 | |||

1625nm ≤0.24 | |||

Cut-off wavelength (nm) |

2m(λc) 1150~1330 |

||

20m cable +2m fiber (λcc) <1260 | |||

Dispersion |

Zero dispersion wavelength(m) 1300~1322 |

||

Zero dispersion slope(ps/nm2.Km) ≤0.092 | |||

Chromatic dispersion |

1285~1330nm ≤3.1 |

||

1550nm ≤18 | |||

1625nm ≤22 | |||

|

Fiber color |

blue, orange, green, brown, slate, white, red, black, yellow, violet, pink and aqua |

|

Fiber Colors:

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

Color |

Blue |

Orange |

Green |

Brown |

Gray |

White |

NO. |

7 |

8 |

9 |

10 |

11 |

12 |

Color |

Red |

Black |

Yellow |

Violet |

Pink |

Aqua |

Packing:

Fiber |

Cable length km |

N.W. ( Approximate) kg |

G.W. (Approximate) kg |

Wooden drum packing size cm |

2-30 |

2 |

140 |

190 |

90×90×70 |

3 |

210 |

265 |

100×100×70 |

|

4 |

280 |

340 |

100×100×70 |

|

32-60 |

2 |

160 |

215 |

100×100×70 |

3 |

240 |

300 |

110×110×70 |

|

4 |

320 |

395 |

125×125×70 |

|

60-72 |

2 |

180 |

235 |

100×100×70 |

3 |

270 |

330 |

110×110×70 |

|

4 |

360 |

435 |

125×125×70 |

|

96 |

2 |

210 |

270 |

110*110*70 |

3 |

315 |

375 |

125*125*70 |

|

4 |

420 |

500 |

125*125*90 |

|

144 |

2 |

250 |

325 |

125*125*70 |

3 |

375 |

465 |

140*140*85 |

|

4 |

500 |

605 |

160*160*105 |

|

Packing information |

Wooden drum , or iron drums or as the customer’s requirement |

|||

Production workshop:

Quality verification:

Packaging:

FAQ:

Q1: How to choose the right optical cable?

Choosing an optical cable requires considering factors such as transmission distance, data rate, environmental conditions, and connection methods. You can provide your specific requirements, and our professional technical team will recommend the suitable optical cable Products for you.

Q2: What’s the MOQ?

The MOQ of Fiber Optic cable depends on the product model and customer needs. You can consult our sales personnel for more details.

Q3: What’s delivery time?

Our delivery time is generally 3-15 working days. The specific delivery time will be determined based on the order quantity and production schedule.

Q4: Why are optical cable prices on the market so varied?

The price differences in optical cables are the result of multiple factors. When choosing optical cables, you should consider price, quality, brand, and after-sales service comprehensively to select products that meet your needs.

Q5: Is it possible to customize optical cables with special specifications?

Absolutely! We will have detailed discussions with you to understand your needs. Then, our engineers will design the optimal Solution based on your requirements. We will produce samples for your testing and confirmation. Finally, we will arrange mass production according to your confirmation.