Description:

The 48C ADSS Double Jacket Fiber Optic Cable is a durable and high-performance Solution for aerial installations, supporting spans of up to 600 meters. Its All-Dielectric Self-Supporting (ADSS) construction eliminates the need for metallic components, ensuring immunity to electromagnetic interference and lightning, making it ideal for areas with electrical noise or harsh weather conditions.The double jacket design enhances the cable's durability, offering superior resistance to UV radiation, temperature changes, wind, and abrasion, ensuring long-term reliability. With 48 optical fibers, the cable supports high-capacity data transmission with minimal signal loss, meeting the demands of telecommunications backbones, ISP networks, and utility applications.Lightweight and easy to install, the cable reduces sagging and requires minimal maintenance, lowering operational costs. Combining robust tensile strength with dependable performance, it is an excellent choice for modern, high-speed networks requiring efficient and reliable long-distance communication.

MOQ: |

10KM |

Packaging: |

Wooden drum |

Delivery Time: |

5-25 days |

Length: |

Customization |

Brand : |

OEM |

Model Number: |

ADSS Fiber Optic Cable |

Place of Origin: |

Jiangsu,China |

Certification: |

ISO9001 |

Detail Information:

Fiber Count: |

48F |

Fiber Type: |

G652D,G655D,OM1,OM2 |

Fiber Brand: |

YOFC,HTGD |

Application: |

Aerial |

Span |

600m |

MAT |

3600N |

MAX Wind resistance |

25m/s wind speed + 5mm Ice Load |

Technical parameters:

Cable fiber count |

/ |

48 |

|

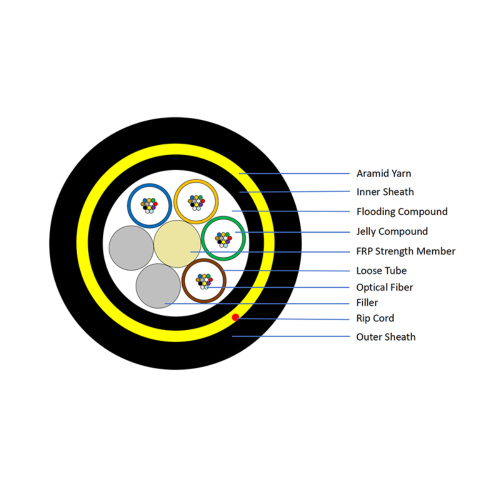

Structure |

/ |

1+6 |

|

Fiber style |

/ |

G.652D |

|

Central strength member |

material |

mm |

FRP |

Diameter(average) |

2.0 |

||

Loose Tube |

Material |

mm |

PBT |

Diameter(average) |

2.0 |

||

Thickness(average) |

0.35 |

||

Max fiber/loose tube |

12 |

||

Tubes color |

Full color identification |

||

Water resistance |

Material |

/ |

Flooding Compound&Water Blocking Tape |

Additional Strength Member |

Material |

/ |

Aramid Yarn |

Inner sheath |

Material |

mm |

HDPE |

Thickness |

0.8 |

||

Outer sheath |

Material |

mm |

HDPE |

Thickness |

1.8 |

||

Cable diameter(average) |

mm |

12.5 |

|

Cable weight (Approximate) |

kg/km |

130 |

|

Attenuation coefficient(Max) |

1310nm |

dB/km |

≤0.35 |

1550nm |

≤0.21 |

||

Rated Tensile Strength(RTS) |

kn |

30Kn |

|

Max allowed tension( MAT) |

kn |

12Kn |

|

Wind velocity |

m/s |

25 |

|

Icing |

mm |

5 |

|

Span |

M |

600 |

|

Crush resistance |

Long term |

N/100mm |

≥1100 |

Short term |

≥2200 |

||

Permission Bent Radius |

static |

mm |

10D |

dynamic |

20D |

||

Temperature |

When laying |

℃ |

-10~+60 |

Storage and transportation |

-40~+70 |

||

running |

-40~+70 |

||

Scope of application |

Suitable for voltage level under 110kV, wind speed below 25m/s, icing 5mm |

||

Cable Marks |

Printing according to customer's requirements |

||

Fiber Colors:

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

Color |

Blue |

Orange |

Green |

Brown |

Gray |

White |

NO. |

7 |

8 |

9 |

10 |

11 |

12 |

Color |

Red |

Black |

Yellow |

Violet |

Pink |

Aqua |

G652D Fiber Data Sheet :

Item |

Specification |

Fiber type |

Single mode |

Fiber material |

Doped silica |

|

Attenuation coefficient @ 1310 nm @ 1383 nm @ 1550 nm @ 1625 nm |

£ 0.36 dB/km £ 0.32 dB/km £ 0.22 dB/km £ 0.30 dB/km |

Point discontinuity |

£ 0.05 dB |

Cable cut-off wavelength |

£ 1260 nm |

Zero-dispersion wavelength |

1300 ~ 1324 nm |

Zero-dispersion slope |

£ 0.092 ps/(nm2.km) |

|

Chromatic dispersion @ 1288 ~ 1339 nm @ 1271 ~ 1360 nm @ 1550 nm @ 1625 nm |

£3.5 ps/(nm. km) £5.3 ps/(nm. km) £18 ps/(nm. km) £22 ps/(nm. km) |

PMDQ (Quadrature average*) |

£0.2 ps/km1/2 |

Mode field diameter @ 1310 nm |

9.2±0.4 um |

Core / Clad concentricity error |

£ 0.5 um |

Cladding diameter |

125.0 ± 0.7 um |

Cladding non-circularity |

£1.0% |

Primary coating diameter |

245 ± 10 um |

Proof test level |

100 kpsi (=0.69 Gpa), 1% |

|

Temperature dependence 0℃~ +70℃ @ 1310 & 1550nm |

£ 0.1 dB/km |

G655D Fiber Data Sheet :

Characteristic |

Condition |

Data |

Unit |

Optical properties | |||

Attenuation |

1550nm 1625nm |

≤0.22 ≤0.24 |

dB/km dB/km |

|

Relative wavelength attenuation @1550nm |

1525~1575nm |

≤0.02 |

dB/km |

Dispersion in the wavelength range of |

1530~1565nm 1565~1625nm |

≥2.0 ≤6.0 ≥4.5 ≤11.2 |

ps/(nm.km) |

Zero dispersion wavelength |

|

≤1520 |

nm |

|

A zero-dispersion slope A zero-dispersion slope typical value |

|

≤0.084 0.075 |

ps/(nm2.km) ps/(nm2.km) |

|

Polarization Mode Dispersion Coefficient PMD Single fiber maximum Fiber link value(M=20,Q=0.01%) Typical value |

|

≤0.20 ≤0.08 0.04 |

ps/ ps/ ps/ |

Cable cut-off wavelength (λcc) |

|

≤1450 |

nm |

Mode field diameter MFD |

1550nm |

9.6±0.5 |

μm |

Effective group refractive index |

1550nm&1625nm |

1.469 |

|

Attenuation discontinuities |

1550nm |

≤0.05 |

dB |

Geometric characteristics | |||

Core diameter |

|

124.8±0.7 |

μm |

Cladding roundness |

|

≤1.0 |

% |

Coating diameter |

|

245±7 |

μm |

Coating / package concentricity error |

|

≤12.0 |

μm |

Coating roundness |

|

≤6.0 |

% |

Core / package concentricity error |

|

≤0.6 |

μm |

The warpage (radius) |

|

≥4 |

m |

Environmental characteristics(1310nm、1550nm、1625nm) | |||

Temperature additional attenuation |

-60℃ ~+85℃ |

≤0.05 |

dB/km |

Temperature-humidity cycle additional attenuation |

-10℃ ~+85℃,98% Relative humidity |

≤0.05 |

dB/km |

Flooding additional attenuation |

23℃,30 days |

≤0.05 |

dB/km |

Hot and humid additional attenuation |

85℃ and 85% Relative humidity,30 days |

≤0.05 |

dB/km |

Dry heat aging |

85℃ |

≤0.05 |

dB/km |

Mechanical properties | |||

Screening tension |

|

≥9.0 |

N |

The macro bend Additional attenuation(100 circle Ф50mm) |

1310nm和1550nm |

≤0.05 |

dB |

Coating peeling force |

Typical average Peak value |

1.5 ≥1.3 ≤8.9 |

N N |

Dynamic fatigue parameters |

|

≥20 |

|

Mechanical & Environmental Performance Test

Item |

Test Method |

Acceptance Condition |

|

Tensile Strength IEC 794-1-2-E1 |

- Load: Short term tension - Length of cable: about 50m |

- Loss change £ 0.1 dB @1550 nm - No fiber break and no sheath damage. |

|

Crush Test IEC 60794-1-2-E3 |

- Load: Short term crush - Load time: 1min |

- Loss change £ 0.05dB@1550nm - No fiber break and no sheath damage. |

|

Impact Test IEC 60794-1-2-E4 |

- Points of impact: 3 - Times of per point: 1 - Impact energy: 5J |

- Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

|

Temperature Cycling Test YD/T901-2001-4.4.4.1 |

- Temperature step: +20oC→-40oC→+70oC →+20oC - Time per each step: 12 hrs - Number of cycle: 2 |

- Loss change £ 0.05 dB/km@1550 nm - No fiber break and no sheath damage. |

Packing:

Fiber |

Cable length km |

N.W. ( Approximate) kg |

G.W. (Approximate) kg |

Wooden drum packing size cm |

2-30 |

2 |

140 |

190 |

90×90×70 |

3 |

210 |

265 |

100×100×70 |

|

4 |

280 |

340 |

100×100×70 |

|

32-60 |

2 |

160 |

215 |

100×100×70 |

3 |

240 |

300 |

110×110×70 |

|

4 |

320 |

395 |

125×125×70 |

|

60-72 |

2 |

180 |

235 |

100×100×70 |

3 |

270 |

330 |

110×110×70 |

|

4 |

360 |

435 |

125×125×70 |

|

96 |

2 |

210 |

270 |

110*110*70 |

3 |

315 |

375 |

125*125*70 |

|

4 |

420 |

500 |

125*125*90 |

|

144 |

2 |

250 |

325 |

125*125*70 |

3 |

375 |

465 |

140*140*85 |

|

4 |

500 |

605 |

160*160*105 |

|

Packing information |

Wooden drum , or iron drums or as the customer’s requirement |

|||

Production workshop:

Quality verification:

Package:

FAQ:

Q1: How to choose the right optical cable?

Choosing an optical cable requires considering factors such as transmission distance, data rate, environmental conditions, and connection methods. You can provide your specific requirements, and our professional technical team will recommend the suitable optical cable Products for you.

Q2: What’s the MOQ?

The MOQ of Fiber Optic cable depends on the product model and customer needs. You can consult our sales personnel for more details.

Q3: What’s delivery time?

Our delivery time is generally 5-25 working days. The specific delivery time will be determined based on the order quantity and production schedule.

Q4: Why are optical cable prices on the market so varied?

The price differences in optical cables are the result of multiple factors. When choosing optical cables, you should consider price, quality, brand, and after-sales service comprehensively to select products that meet your needs.

Q5: Is it possible to customize optical cables with special specifications?

Absolutely! We will have detailed discussions with you to understand your needs. Then, our engineers will design the optimal solution based on your requirements. We will produce samples for your testing and confirmation. Finally, we will arrange mass production according to your confirmation.

From start to finish, we ensure quality and care —smooth production, safe delivery!