Introduction

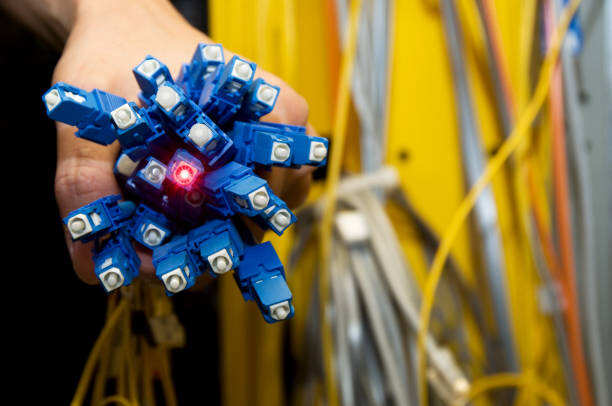

These Fiber Optic Splice Closures are necessary in ensuring the continuity and reliability of modern-day communication networks. Downtime leads to network instability, when damage does occur (and it will), quick emergency repairs are essential. These repairs require fiber optic connectors. In that case, this article discusses a basic guide on proper use of fiber optic connectors for emergency repair.

Application of fiber optic splices in the emergency repair of optical cable joint boxes

When the fiber optic splices are used for emergency repair of optical cable joint boxes, first implement fault breakpoint test and positioning to determine the access points by technical means after which other tools can be directly placed. Through the test system, fault breakpoint tests can be performed by transmission monitoring personnel before arriving at On-Point, so that emergency repair personnel come to maintenance point timely after having break-point. If the fault point is unclear, and a more accurate location cannot be derived in terms of specific position, you should open up one joint box for two-way test as soon as possible to find it. Longer optical cable or emergency micro cable can be replaced for maintenance; if the fault point is clear and the old line length is long enough, it should also meet normal pole position conditions so that section of a cable optic break-point failure new short joints to abnormal positions.

Optical cable joint box-poly fiber cable communication

Run the fault emergency according to step 2 After finding out the break point, connect optical fiber in distribution box following emergency connection steps. For the emergency fiber fixing method, in accordance with the "first rush to repair", on time and quickly as possible restoration of optical communication. Place the optical fibers to be connected in close Contact with each other into a splicer, then rotate and cover on cam to protect the optical fiber. The process is separated: remove the sheath of your optical cable first, use a fiber stripping pliers to slice off about 45 mm outer sheathing of your optic cable after opening the bottom locating groove for fibers and pushing it into this groove transparently with upper cover closing followed by locking in place using an optical fiber gripping slider pushed upwards simultaneously. The optical fiber splicer is completed, the special card slot of the splice box and fixed in the optical cable splice box.

Operation of fault emergency

After judging the location of the faulty point, connect using another optical cable line in the small fiber optic splice closure following these guidelines: When conducting emergency repair, we should adhere to the principle of "rush and restore electrical optical communication network". Insert the optical fibers to be fused into the splicer until they are in touch, and then rotate a cam element of one mechanical apparatus providing locking and protecting function for an optical fiber. In the actual operation, first of all, remove the outside sheath of optical cable and open the top cover( also called upper body), insert fiber into bottom locating groove which will be buckle by gravity to clamp instruments or slide lock.

After completing the installation, place the optical fiber splicer and fix it in one of these specially designated slots for a splice box that is already provided within your own optical cable splice case.

Emergency repair confirmation and subsequent maintenance

The emergency repair can be completed smoothly, but we must do a good job in the follow-up work of confirming that the emergency is repaired after starting it up On-site emergency repair personnel should notify transmission surveillance to check whether the network is restored. Network is restored to its original state — emergency repair done. Check the connection status, if NOT back to normal contact situation or find 0=> condition multiple nodes fault breakpoints. Furthermore whether the sealing of, for example optical cable joint box is good and whether its appearance are complete or not. When consequences occur, it must be replaced in time; and an analysis shall also be made for the factors that may lead to a recurrence of failure during use after joint box replacement so as to have far-reaching effects on surrounding environment.

Conclusion

The connection method of the optical fiber splice is a cold connect, which takes less time to use and is more reliable than using fusion processes as well it does not have any valuable economic costs for an emergency repair process. The optical cable splices should be used as emergency repair splicing accessories in order to guarantee the efficiency and effect of the emergency repair work for the two sections, And ensure normal communication passes through that section. In the specific application, must be in strict accordance with " Installation Instructions ", trouble break point test positioning and emergency repair worker operation Troubleshooting after confirmation of trial and post-maintenance work, to ensure that optical cable lines safe...