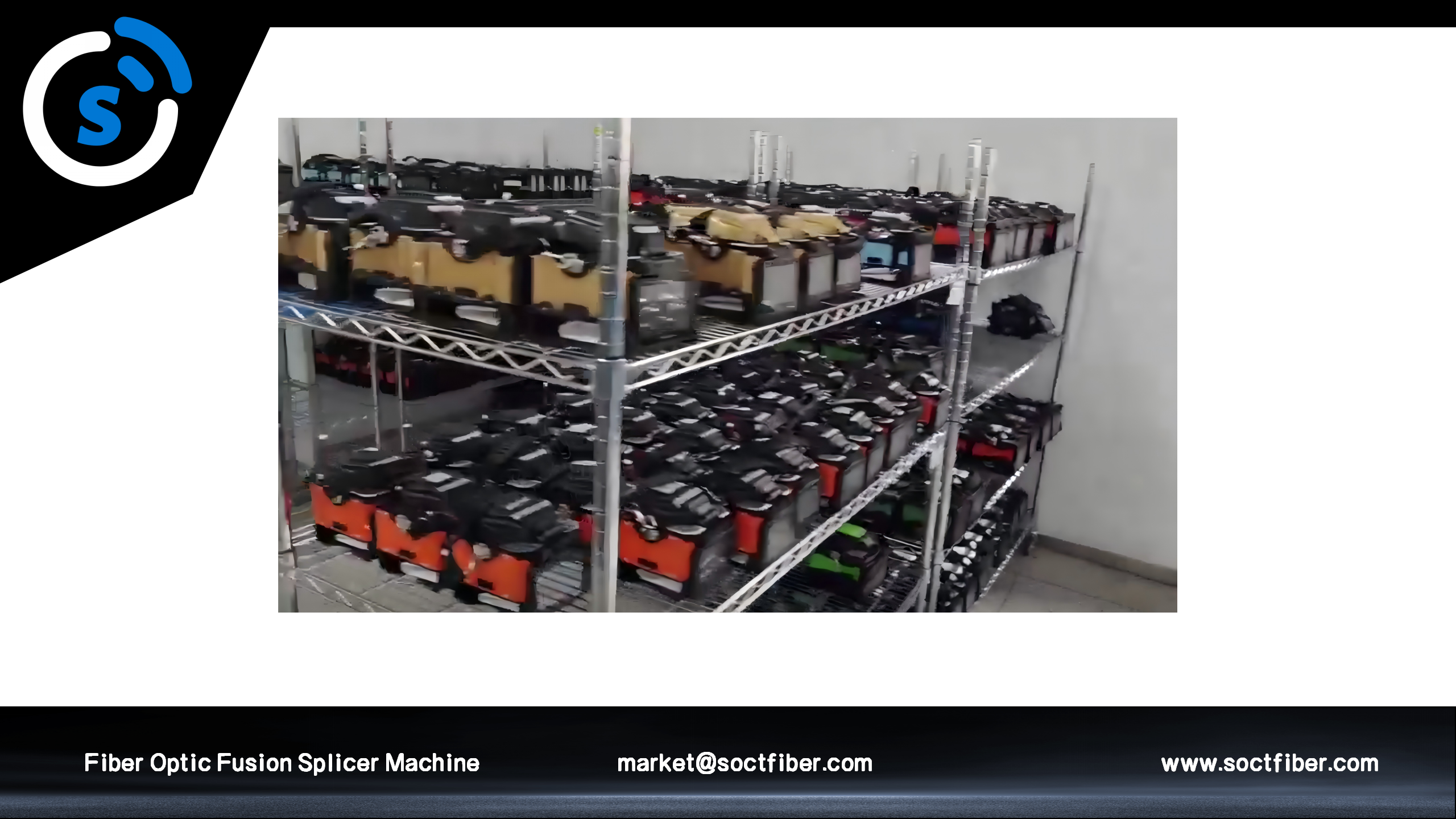

optical fiber fusion splicer supplier

Manufacture of conductor products, such as its optical fiber fusion splicer machine and other related products.

Three operating functions are performed by the optical fiber fusion splicer:

These fusion splicers use an advanced precision aligning system, fast heating process and an automated loss estimation of splices to achieve their high performance. These features ensure that low-loss, high-strength splice connections may be made - vital for maintaining signal integrity in telecommunication networks, data centers and cable television systems alike.

Other applications of the splicer abound, from repairing and regional networking to the FTTH systems, no matter where However while it is indispensable to technicians and engineers who are working in those fields across a country serving hundred thousands of homes, because network installed they can guaranteed either way at any time.