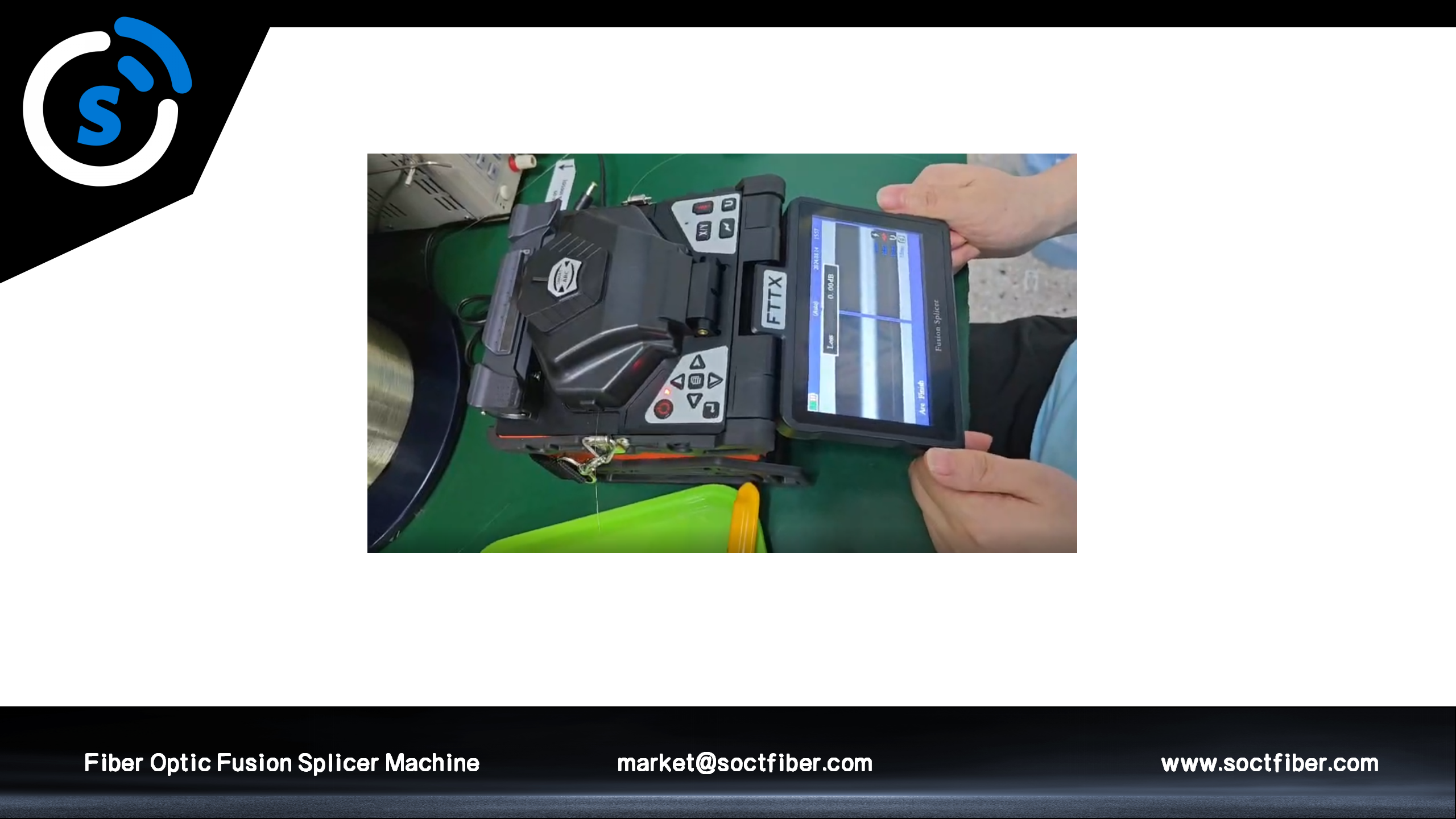

fusion splicer optical fiber testing procedures

These procedures measure loss of light in the fiber -- one is fused butt end-to butt end with a high-power soldering iron and the other is butted alongside it from below using a precision screwdriver, while a third is held in place at right angles so that its two ends can be visualized through the endoscope. Splicing technologies vary widely between manufacturers, but the advent of precision mechanical splicing permitted fibre arrays to be built with efficiency approaching 100%. It is also possible for external inspection systems to check the quality of the fusion splicing - this requires a UV source to be glow-discharged under atmospheric pressure, while automatic laser microscopes carry out remote sensing. By contrast, the full inspection and analysis capabilities of these testers are dealt with in Chapter 5 (Combining splicing and testing "spectrum"—an introduction). Varieties of this test include not only the store-and-forward type, which retains an entire length of light path inside field splice gaskets block ing through pre-formed unitizing device; but also versions built without storage features. From telecommunications and datacom down to cable television and premise cabling networks, in various applications optical fiber systems need optimal performance. As aresult, proper maintenance testing by means of FISION Splices Optical Fiber Testing Equipment must be a top priority.