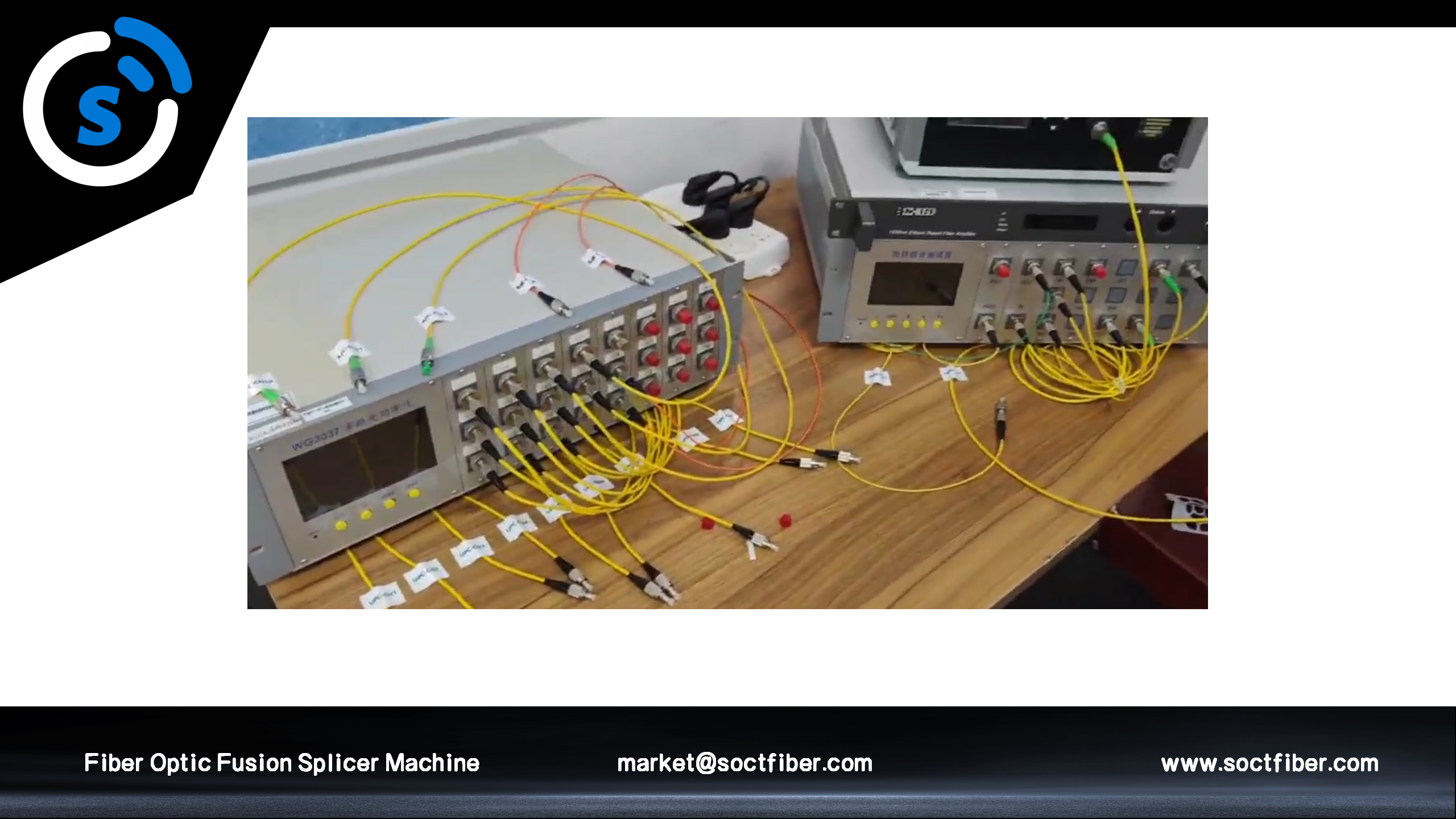

fiber optics fusion splicer

The fiber optics fusion splicer is a sophisticated piece of equipment designed to join two or more optical fibers together permanently by fusion.To begin with, two fiber ends have to be precisely aligned in this process and an electric arc used to melt them. Then they are cooled so that molten fibers become solidified into one continuous single fiber.The main functions of a fiber optics fusion splicer include high-precision alignment, efficient heating and cooling cycles, and the ability to maintain signal integrity across its splice.As a tool for technicians, it has many technological features; including an intuitive user interface configured to follow industry standard conventions; rugged construction so as not to be delicate when it is taken out into the field or laboratory for work; domain players transparently wide ranging KWatics; automatic splice programs guarantee cost-effective maintenance routines.Example applications range from telecommunications and voice centers to cable TV and fiber-to-the-home installations.