Blog

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

Share some precautions for optical cable construction specifications

Introduction

The optical cable construction, often overlooked in our daily life. The need for optical cable connection is becoming more and more important as high-speed data transmission accelerates. Maintaining The Construction Specifications When Deploying Optical Cable Networks Is Vital For Building A Network That Will Be Successful And Well Supported Over Time. This post provides a list of important precautions and good practices to follow to keep the performance characteristics and long life for optical cables.

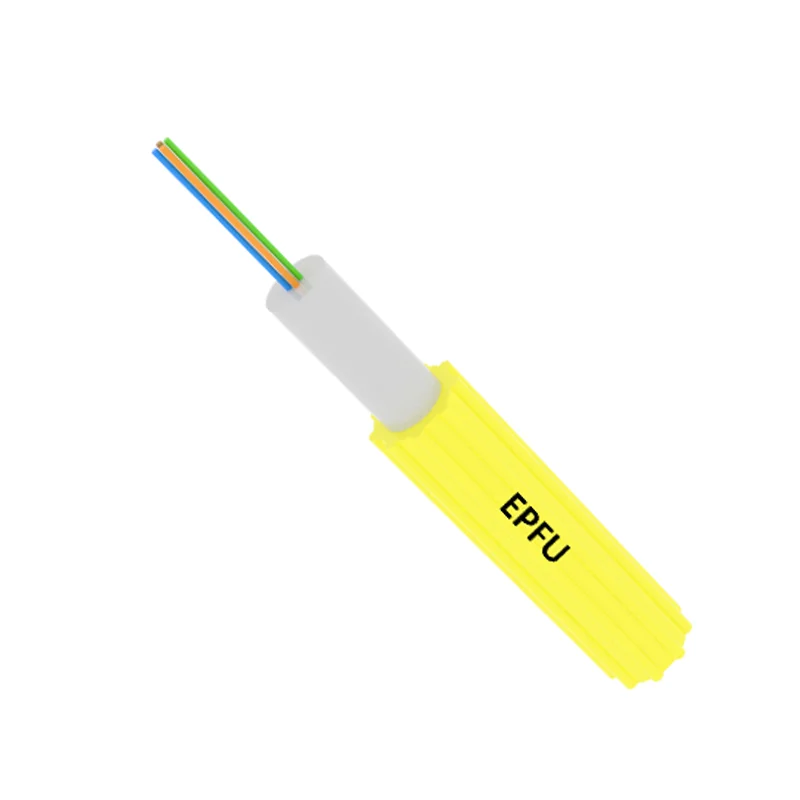

Selection of Cable Type and Specification

The selection of optical cable type and specifications is the first step in the construction process. Various types of optical cables are designed for different applications and ranges, such as single-mode or multi-mode. They ensure that cables with the right specifications are used in each application to meet data transmission and distance requirements. Furthermore, the cable specifications you choose will also depend on environmental factors like temperatures and humidity as well any potential exposure to corrosive materials.

Safety Measures for Cable Installation

Correct installation is the key to ensure optical cables perform and last. The most important thing to take care of is the minimum bending radius, so that we do not break any fibers mechanically. Bending radius: 15 x diameter at least, some design up to 20x for extra security. Cables should also be kept in its right storage before and during installation to avoid damage that may result from exposure, or being touched. Cables are to be handled very carefully as they have ratings on side of cables so that it does not put extra tension around the installation and which might break some fibers.

Joint and Splicing Considerations

In the process of joining or splicing optical cables, it is necessary to operate in a clean environment so as not to contaminate them (based on how minuscule these things are which determines their sensitivity). These are highly specialized tools where accuracy is essential; coupled with proper joint/splice documentation, for future reference and maintenance. Having this documentation can be very useful when it comes to debugging and making sure the network stays solid for many years from now in future!

Safe Guarding Devices and Assisting Techs

The biggest cost optimization for optical cable is to ensure the physical performance of prevention before and after construction through installation, care measures. Bungee cords should be firmly secured to avoid any shifting or damage from external sides. Depending on the circumstances and hazards, cables should be run inside conduits for protection. One should think carefully about long term protection against environmental exposure, such as UV radiation, water ingress and rodent damage too.

Test and Inspection Process

Subsequent to the installation of these cables, they are thoroughly tested in order to verify that the optical cable network remains sound. To do this, inspection should be conducted regularly to evaluate the condition and performance of the cable in order to detect any potential problem before it turns into a critical breach. This includes carrying out a maintenance schedule based on test results and manufacturer recommendations to catch any problems before they become widespread.

Safety Rules and Regulations

Optical cable construction is strictly in accordance with local and international safety standards. The workers installing the system should all be educated on safe practices to prevent injury and maintain code compliance. On the other hand, acquiring necessary permits and being guided by regulatory principles in construction of cable is equally important to prevent legal enforcers crashing into your activity at one time or another — all determined on ensuring that work safety guideline are put into consideration.

Documentation and Record Keeping

It is important to have records from where each cable was run, and what type or specification of which cables were used for that network. Documentation for anything that deviates from the original construction plan should be maintained, and all records kept intact an organized so it can quickly access as needed.

Operates in environmental and sustainability circumstances.

With environmental concerns surrounding the construction of optical cables, it becomes crucial to do so in a way that reduces their impact. To The Good Work We Say Instead Consider More Sustainable Materials and Practices And Definitely Make Sure You Have Optics In There, As Planning for Whole of Life Fill Of Optical Cables Is An Important Part in the Responsible Construction Mix

Conclusion

The long-established optical cable network construction specifications and deployment experience play an important role in the successful deployment of associated works. Every step carries certain importance to maintain the reliability of optical cables, from choosing correct type of cable wires until post-installation testing and regular maintenance. The advancements in telecoms industry will continue to grow and this requires ensuring optical cable construction is done accurately underscores the necessity of continuous monitoring for any move from best practices.