Blog

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

My Personal Understanding of Hollow-Core Fibers

Back in 2022, I told everyone a joke. Looking back now, I realize I was the joke myself. That’s why it’s crucial to read more and learn more. In fact, both solid-core fibers and hollow-core fibers exist. Below is my personal understanding of hollow-core fibers.

let’s Compare hollow-core fibers with solid-core fibers.

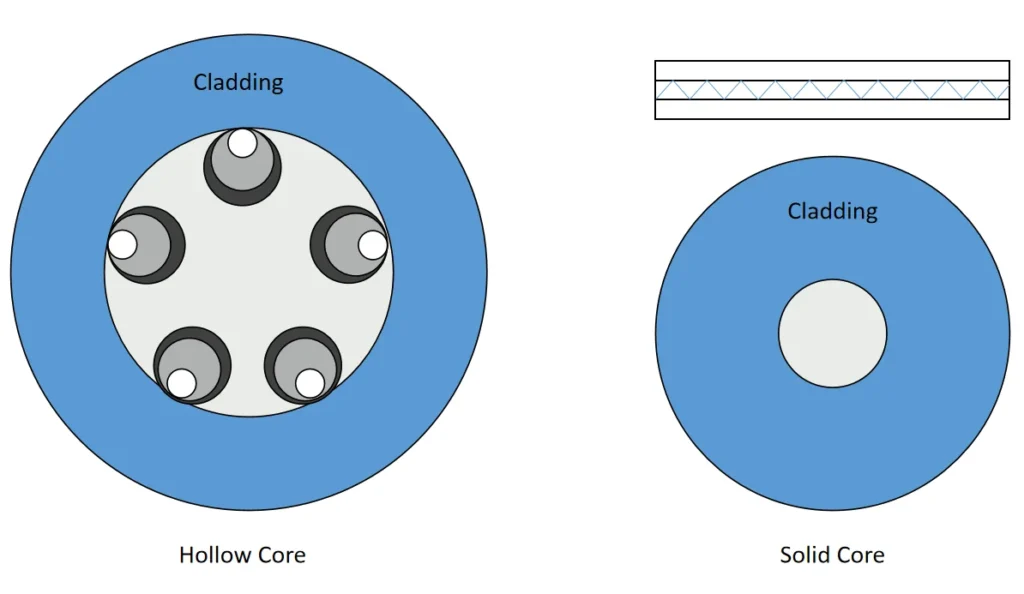

Both consist of a core and a cladding, but hollow-core fibers have additional microstructures. The function of these microstructures is to confine light within the core (for transmission in air) through reflection—or, to put it simply, via an interference mechanism. Traditional solid-core fibers rely on the total internal reflection (TIR) principle to trap light within the core for transmission, preventing light leakage. Hollow-core fibers work similarly: they confine light within the core, but the light travels through air instead.

Many people wonder why hollow-core fibers offer such high transmission speeds.

Some assume it’s because light bounces back and forth (refracts repeatedly) in solid-core fibers, taking a longer path, while in hollow-core fibers, light travels straight through air—thus covering a shorter distance. But this is incorrect: light can only travel in a straight line, yet it’s impossible for fibers (whether solid or hollow) to be laid in a perfectly straight line during manufacturing and cable deployment. There will always be bends, so light in hollow-core fibers also undergoes reflection; the difference is that microstructures reflect light back into the core.

Different transmission media

The real reason for the significant speed increase lies in the different transmission media. In solid-core fibers, light travels through glass at a speed of approximately 200 million meters per second, whereas in air (the medium in hollow-core fibers), light travels at around 300 million meters per second—resulting in a speed boost of over 30%.

Different loss

Additionally, light in glass is subject to Rayleigh scattering and other scattering effects, leading to higher attenuation. For solid-core fibers operating at the 1550 nm wavelength, the attenuation is roughly 0.22 dB per kilometer, while hollow-core fibers can achieve an attenuation as low as 0.09 dB per kilometer—a reduction of more than 50%. This means that, under the same conditions, the transmission distance of hollow-core fibers can be nearly doubled.

Lower dispersion, higher capacity

Moreover, light transmission in air results in lower dispersion and higher capacity. For example, high-power lasers cannot be transmitted through solid-core fibers, as the glass would be damaged (burnt out) by the laser. Another characteristic of hollow-core fibers is their larger diameter (much thicker than solid-core fibers), which leads to poorer bend resistance.

Transmission testing solutions

However, since light travels in air with minimal Rayleigh scattering, optical time-domain reflectometers (OTDRs)—which rely on Rayleigh scattering for testing—are no longer suitable for hollow-core fibers, making maintenance more cumbersome.

Our current solution is to bundle hollow-core fibers and solid-core fibers into a single optical cable for deployment. If the cable is broken, we can locate the fault by testing the traditional solid-core fibers and perform repairs. Meanwhile, hollow-core fibers require polarization-maintaining (PM) fusion splicers for splicing. These splicers are large and require ample operating space, so we usually need to strip a relatively long section of the cable during preparation.

The splicing of hollow-core fibers also has strict requirements for ambient temperature and humidity, making the process extremely challenging. In harsh environments, it may be necessary to strip 4–5 meters of the cable, and even then, successful splicing cannot be guaranteed.

The cost of hollow-core fibers

Finally, regarding the cost of hollow-core fibers: it is approximately $5,285 per core per kilometer—that is, $5.285 per core per meter, which can be described as “sky-high.” This cost is more than 1,000 times that of traditional solid-core fibers (the cost of solid-core fibers is roughly ¥2,142.86 per kilometer for a 4-core cable). Therefore, widespread infrastructure deployment of hollow-core fibers will require more time to reduce costs.