Blog

Popular Blogs

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

How to Choose Outdoor Fiber Optic Cables

So far, SoctFiber’s fiber optic cable factory has maintained a customer complaint rate of less than 1%. We provide timely support for our clients, including logistics coordination, product replacement in case of damage, and customized fiber optic cable solutions tailored to their specific project needs.

In modern telecommunication network projects, SoctFiber offers a wide range of outdoor fiber optic cables, including GYTA (commonly known as duct cable), GYTS (commonly known as aerial cable), GYTA53 (commonly known as direct-buried cable), and GYTZA (commonly known as flame-retardant cable).

So, how can you choose the right fiber optic cable model for your project?

Here are several key factors to consider.

I. Environmental Analysis for Outdoor Cable Installation

When selecting outdoor fiber optic cables, it is essential to analyze the environmental conditions along the installation route:

- Presence of AC electrified railways or high-voltage power transmission lines

- Potential risks of lightning, flooding, or rodent damage

- Historical temperature range and frost depth

- Terrain conditions such as mountainous areas, hills, plains, or paddy fields

According to fiber cable selection principles, outdoor cables used in complex environments must be able to withstand high crush resistance, tensile stress, and wide temperature variations, as well as offer protection against water ingress, lightning, and rodent attacks.

II. Common Types of Outdoor Fiber Optic Cables

1. GYTA Cable (Loose Tube Armored Cable)

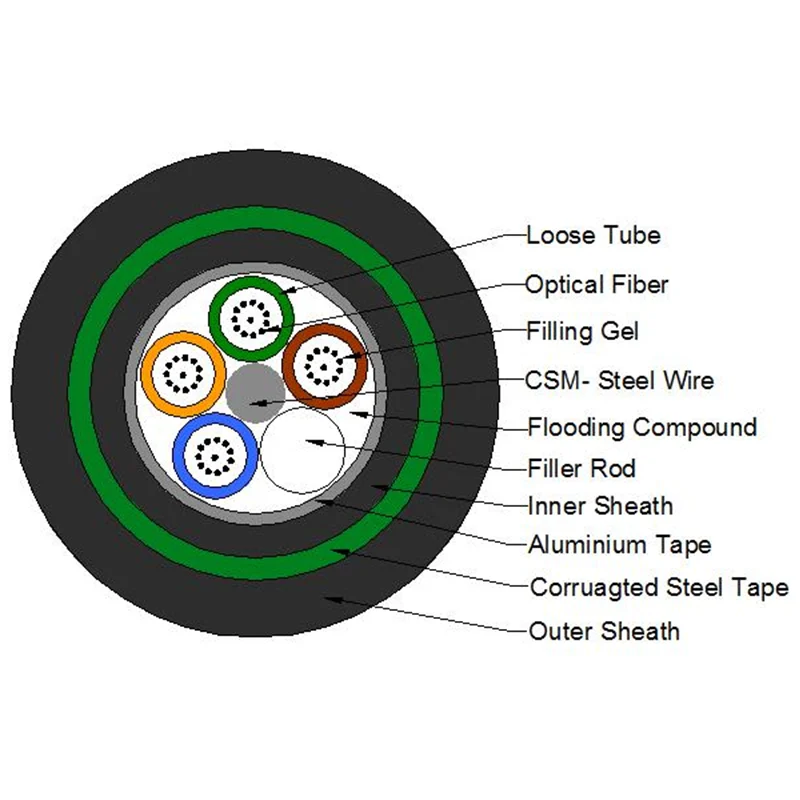

GYTA cable adopts a stranded loose tube structure.

Fibers are placed in loose tubes filled with water-blocking gel. The cable core’s central element is a metal strength member, sometimes coated with polyethylene (PE) for larger fiber counts.

Loose tubes (and fillers, if any) are stranded around the central strength member to form a compact and circular cable core, which is filled with water-blocking compound.

After being longitudinally wrapped with an aluminum tape (APL), an outer PE sheath is extruded to complete the cable.

2. GYTS Cable (Aerial Cable)

The GYTS cable has the same core structure as GYTA, but its armoring layer consists of corrugated steel tape (PSP) laminated on both sides and coated with PE sheath.

This design provides excellent mechanical protection and tensile strength, making it suitable for aerial installations.

3. GYTA53 Cable (Direct-Burial Cable)

GYTA53 is designed for direct burial applications, with double-layer armoring for enhanced protection.

Its performance requirements include:

- Optical characteristics must meet the transmission standards.

- Mechanical strength must withstand pulling and crushing during installation.

- Temperature performance must remain stable under extreme environmental changes.

- The fiber’s optical performance must remain unaffected after transportation, installation, and maintenance.

- The cable design should also consider cost-effectiveness and long-term reliability.

4. GYTZA Cable (Flame-Retardant Cable)

GYTZA has a similar structure to GYTA; however, the outer sheath is made of flame-retardant material instead of standard polyethylene.

This type is primarily used for central office entry points or critical network junctions, typically with section lengths no shorter than 500 meters.

III. Choosing Between Single-Mode and Multi-Mode Outdoor Cables

Outdoor fiber optic cables are mainly used for interbuilding connections or long-distance network links.

Due to their exposure to harsh conditions, outdoor cables are generally armored and designed with higher tensile strength, corrosion resistance, and thicker protection layers than indoor cables.

They are available in single-mode (SM) and multi-mode (MM) types.

1. Single-Mode Outdoor Fiber Cables

Single-mode fibers have a core diameter of 9/125 μm and transmit light through a single propagation mode.

They use lasers or laser diodes (LDs) as light sources and have significantly lower attenuation and dispersion than multimode fibers.

For example, over a distance of 1 km, a multimode fiber may experience up to 50% signal loss, whereas a single-mode fiber may only lose about 6.25%.

Thus, single-mode cables are ideal for long-distance transmission.

2. Multi-Mode Outdoor Fiber Cables

Multi-mode fibers have a core diameter of 50/125 μm and transmit multiple light modes simultaneously, each following a slightly different path.

They typically use LED or VCSEL (Vertical-Cavity Surface-Emitting Laser) sources.

Because of modal dispersion, their transmission distance is limited compared to single-mode fibers.

However, due to the larger core size, multimode fibers are easier to align with connectors and light sources, making them a cost-effective choice for short-distance outdoor LAN connections.

3. How to Choose: Single-Mode vs. Multi-Mode

The transmission distance is the key factor when deciding between single-mode and multi-mode outdoor cables.

- For short-distance links (below 8 km), multimode fiber is preferred due to its lower equipment cost, as LED transceivers are cheaper than laser sources.

- For long-distance transmission (over 8 km), single-mode fiber should be used to ensure low attenuation and stable signal quality.

IV. Key Points to Check When Selecting Outdoor Fiber Cables

1. Check the Packaging

Outdoor cables are typically supplied in 1 km, 2 km, 3 km, or 4 km drums, or custom lengths.

Inspect the packaging for clear labeling, including manufacturer name, cable type, and length markings, and confirm that a test report is included inside the drum.

2. Inspect the Outer Sheath

The sheath of outdoor cables is usually made of polyethylene (PE) or flame-retardant polyethylene.

High-quality outdoor sheaths should have good flexibility, smooth surface, and be easy to strip.

3. Check the Metallic Armoring Layer

Most outdoor cables are armored with a metallic layer to enhance mechanical strength.

The steel or aluminum tape should be phosphated to prevent hydrogen-induced attenuation and corrosion, giving it a gray appearance.

4. Inspect the Fiber Core

The optical fiber core is the most critical component.

Whether the fiber is single-mode (OS2) or multi-mode (OM1/OM2/OM3/OM4) determines the transmission performance.

Always ensure the fibers meet standard specifications and network requirements, as the quality of the fiber core directly affects network connectivity and signal stability.

In summary, selecting the right outdoor fiber optic cable requires a thorough understanding of the installation environment, transmission distance, and mechanical protection requirements.

Take a look at SoctFiber’s automated production lines — you’ll definitely find them impressive and worth your attention.