Application

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

Industry

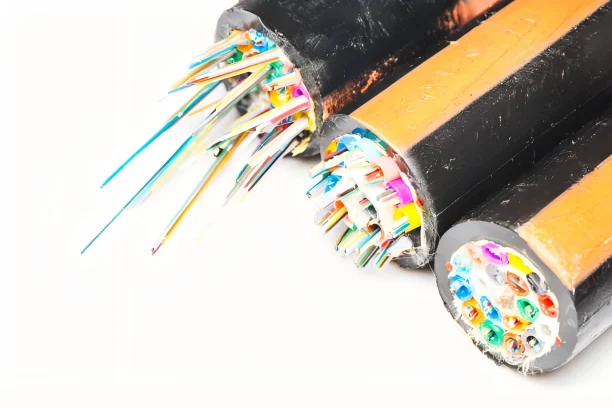

How Are Fiber Optic Cables Transforming Industrial Operations?

Industrial sites struggling with unreliable communication? Old copper wiring failing in harsh conditions? Fiber optics offer a robust, high-performance solution for modern industrial challenges.

Fiber optic cables are transforming industrial operations by providing reliable, high-speed data transmission that is immune to electromagnetic interference and resistant to harsh environmental factors, crucial for automation, control, and safety.

Throughout my career in manufacturing, I’ve seen how crucial robust communication is for efficiency and safety. Many industrial environments are tough on equipment, and traditional copper cables often struggle. When I first started exploring how fiber optics could be applied beyond just telecom or data centers, I realized their potential for industry was enormous. Let’s look at why these advanced cables are becoming so important on the factory floor and in demanding field applications.

Why Is Fiber Optic a Superior Choice for Harsh Industrial Environments?

Facing signal drops and equipment damage in tough industrial settings? Copper cables vulnerable to noise and corrosion? Fiber optics provide unparalleled resilience against common industrial hazards.

Fiber optic cables are superior for harsh industrial environments because they are immune to electromagnetic interference (EMI), resistant to chemical corrosion and moisture, and can operate across wider temperature ranges than copper.

I’ve visited countless industrial sites, from bustling factories with heavy machinery to outdoor installations exposed to the elements. A common thread I’ve seen is the challenge of maintaining reliable communication links. Electrical noise from motors, welders, and high-voltage equipment can wreak havoc on copper-based data signals. Temperature swings, moisture, and even corrosive chemicals can degrade copper cables over time, leading to failures and costly downtime.

Built to Withstand the Toughest Conditions

Fiber optic cables, by their very nature, overcome many of these challenges. Because they transmit data using light pulses through glass or plastic fibers, they are inherently immune to EMI and RFI. This is a massive advantage in electrically noisy industrial environments. Furthermore, the materials used in industrial-grade fiber optic cables are designed for durability.

Let’s break down their advantages:

| Feature | Traditional Copper Cables | Industrial Fiber Optic Cables | Impact in Industrial Settings |

|---|---|---|---|

| EMI/RFI Immunity | Susceptible to interference from motors, VFDs, etc. | Completely immune. | Reliable data transmission even near high-power equipment. |

| Environmental Resistance | Prone to corrosion, degradation from moisture/chemicals. | Can be jacketed with materials resistant to chemicals, UV, abrasion, moisture. | Longer lifespan and reliability in corrosive or wet environments. |

| Temperature Range | Limited operating temperature range. | Can be designed for extreme hot and cold temperatures. | Suitable for outdoor installations, foundries, cold storage. |

| Safety (Spark Hazard) | Can carry electrical current, potential spark risk. | Dielectric (non-conductive), no spark hazard. | Safer for use in volatile environments (e.g., oil & gas, chemical plants). |

| Weight & Size (for capacity) | Heavier and bulkier for equivalent bandwidth. | Lighter and smaller diameter for high bandwidth. | Easier installation in congested conduits, reduced structural load. |

I remember a food processing plant I worked with. They constantly battled signal issues with their control systems due to frequent high-pressure washdowns and the presence of corrosive cleaning agents. Switching to appropriately jacketed fiber optic cables for their critical network links dramatically improved their system uptime and reduced maintenance headaches. This kind of resilience is precisely why fiber is gaining traction across so many industrial sectors.

Which Industries Benefit Most Significantly from Fiber Optic Adoption?

Are outdated communication systems hindering your industry’s productivity and safety? Specific sectors face unique challenges that fiber optics are perfectly suited to address.

Industries like manufacturing, oil & gas, transportation, and energy/utilities benefit most significantly from fiber optics due to needs for high-bandwidth automation, remote sensing in harsh conditions, reliable control networks, and smart grid communication.

While fiber optics offer broad advantages, some industries feel the benefits more acutely because of their specific operational demands and environmental challenges. I’ve seen firsthand how deploying fiber can be a game-changer in sectors where reliability, bandwidth, and safety are absolutely paramount. These aren’t just incremental improvements; they can fundamentally change how these industries operate.

Tailored Solutions for Demanding Sectors

Let’s look at a few key industries and how they leverage fiber:

- Manufacturing (Smart Factories / Industry 4.0): Modern factories rely heavily on automation, robotics, machine vision, and Industrial Internet of Things (IIoT) sensors. These generate vast amounts of data that need to be transmitted reliably and with low latency for real-time control and monitoring. Fiber provides the necessary bandwidth and EMI immunity in environments filled with motors and machinery. I’ve seen assembly lines become much more efficient and adaptable after upgrading their network backbone to fiber.

- Oil & Gas: This sector involves operations in extremely harsh and often remote locations, from offshore platforms to desert pipelines. Fiber optics are used for downhole sensing (temperature, pressure), secure data transmission from remote sites, and control systems in potentially explosive atmospheres where their non-conductive nature is a major safety plus.

- Transportation (Railways, Highways, Airports): Reliable communication is critical for signaling, traffic management, surveillance, and passenger information systems. Fiber optic cables offer long-distance transmission capabilities with minimal signal loss, resistance to outdoor environmental conditions, and immunity to electrical interference from power lines or electrified rail systems.

- Energy & Utilities (Power Generation & Distribution): Smart grid initiatives require extensive communication networks to monitor and control power distribution, manage substations, and integrate renewable energy sources. Fiber optics provide the secure, high-bandwidth, and EMI-resistant communication needed for these critical infrastructure applications. I’ve worked on projects where fiber helped improve grid stability and response times.

Here’s a summary of the fit:

| Industry | Key Fiber Optic Advantages Utilized | Example Applications |

|---|---|---|

| Manufacturing | High bandwidth, EMI immunity, reliability for automation. | Robotic control, machine vision, IIoT networks, factory floor data collection. |

| Oil & Gas | Harsh environment resistance, safety (non-sparking), long distance. | Downhole sensing, SCADA systems, remote platform communication, pipeline monitoring. |

| Transportation | Long distance, EMI immunity, outdoor durability. | Railway signaling, traffic control, airport surveillance, passenger information. |

| Energy/Utilities | EMI immunity, security, reliability for critical infrastructure. | Smart grids, substation automation, renewable energy integration, sensor networks. |

The common theme is that as industries become more data-driven and automated, the need for a robust and high-performance communication backbone like fiber optics becomes increasingly undeniable.

What Future Innovations Will Further Expand Fiber Optics in Industry?

Is current fiber technology the final word for industrial use? Absolutely not. The industry is continuously developing solutions to meet evolving industrial demands and open up new applications.

Future innovations expanding industrial fiber optics include more specialized and ruggedized cable designs, integrated sensing capabilities (Distributed Fiber Optic Sensing), easier field termination/repair, and cost reductions making it accessible for more applications.

The pace of technological change is relentless, and that’s certainly true for industrial communication. What’s considered cutting-edge today becomes standard tomorrow. Based on what I’m seeing in the fiber optic manufacturing world and hearing from industrial clients, there are several exciting developments on the horizon that will make fiber even more integral to industrial operations. We’re always looking for ways to make the technology more powerful, easier to use, and more cost-effective for a wider range of applications.

Pushing the Boundaries of Industrial Connectivity

The evolution of fiber optics for industry is focused on enhancing performance in specific industrial contexts and making it more practical to deploy:

- Specialized Industrial Cable Constructions: While current industrial cables are robust, there’s ongoing development for even greater resistance to specific challenges:

- Enhanced chemical and solvent resistance for process industries.

- Extreme temperature cables for foundries or cryogenic applications.

- Cables with superior crush, impact, and abrasion resistance for mobile equipment or direct burial.

- Hybrid cables combining fiber with power conductors for simplified installations.

- Distributed Fiber Optic Sensing (DFOS): This is a fascinating area. The fiber optic cable itself can act as a continuous sensor, detecting changes in temperature (DTS), strain (DSS), or acoustics (DAS) along its entire length. Imagine a pipeline where the fiber cable not only carries data but also detects leaks or ground movement. I believe DFOS has huge potential for structural health monitoring, perimeter security, and process monitoring.

- Easier Field Termination and Repair: One historical challenge with fiber has been the perceived difficulty of terminating or repairing cables in the field compared to copper. Manufacturers are continuously improving field-installable connectors and portable splicing tools to make fiber deployment and maintenance faster and require less specialized skill.

- Cost Optimization and Broader Accessibility: As manufacturing processes for fiber and components become more efficient, and as adoption increases, costs are gradually coming down. This makes fiber a viable option for a wider array of industrial applications, including those in smaller businesses or less critical systems where it might have previously been considered too expensive.

- Integration with Industrial Wireless (e.g., Private 5G): Fiber will often serve as the high-capacity backbone for industrial wireless networks, providing reliable connectivity to wireless access points throughout a facility or large outdoor area.

These innovations are driven by real-world needs:

| Future Innovation Area | Potential Industrial Benefit | Current Focus |

|---|---|---|

| Specialized Cabling | Enhanced reliability in extreme or specific niche environments. | New jacketing materials, armored designs, hybrid constructions. |

| Distributed Sensing (DFOS) | Continuous monitoring over long distances, predictive maintenance. | DTS for temperature, DSS for strain, DAS for acoustics/vibration. |

| Easier Field Handling | Faster deployment, reduced installation costs, quicker repairs. | Improved field connectors, simplified splicing tools, pre-terminated solutions. |

| Cost Optimization | Wider adoption across more industrial segments and applications. | Manufacturing efficiencies, increased volume production. |

| Wireless Backhaul | Enabling robust and reliable private industrial wireless networks. | High-bandwidth fiber links to 5G small cells / Wi-Fi APs. |

The goal is to make fiber optic technology not just powerful, but also practical and adaptable to the ever-evolving landscape of industrial automation and data management.

Conclusion

Fiber optic cables are vital for modern industry. They offer unmatched reliability, speed, and safety, paving the way for smarter, more efficient, and safer industrial operations worldwide.

Related Products

No results found.