Blog

Popular Blogs

- Building A, Republic International Business Plaza, No. 3699 Gonghexin Road, Jing'an District, Shanghai

- +86-21-59175887

- market@soctfiber.com

- 86-17321363317

- 86-13341796231

How are multimode optical fibers classified by grade?

After multimode optical fiber is drawn (pulled into a thin strand from a preform), its grade classification is a precise process of measurement, data analysis, and strict certification based on international standards.

The core of this process is to ensure that the fiber meets the specified metrics for a particular grade (OM1/2/3/4/5) as defined by international standards, by measuring key optical parameters.

Here are the specific procedures and key steps for grade classification after the drawing process:

1. Key Measurement Parameters

During the drawing process, the fiber passes through the draw tower at very high speeds (dozens of meters per second). During this process, online and offline measurement systems will either continuously or sample-based measure the following key performance parameters that determine the fiber’s grade:

Bandwidth: This is the most critical and direct parameter for classifying OM grades. It measures the transmission capacity of the fiber.

Overfilled Launch Bandwidth (OFL BW): This is a traditional measurement method that uses an LED light source to excite all modes. It is primarily used to measure OM1 and OM2 fibers.

Effective Modal Bandwidth (EMB / EMBc): This is the most crucial parameter. For laser-optimized OM3, OM4, and OM5 fibers, a VCSEL laser source must be used for measurements at the 850 nm and 1300 nm wavelengths. The EMB value directly determines the fiber’s actual performance in high-speed networks. Standards require the following:

- OM3: EMB @850nm ≥ 2000 MHz·km

- OM4: EMB @850nm ≥ 4700 MHz·km

- OM5: EMB @850nm ≥ 4700 MHz·km and EMB @953nm ≥ 2470 MHz·km

Refractive Index Profile:

- The bandwidth performance of a multimode fiber is precisely determined by the refractive index distribution of its core (typically a graded-index profile). After drawing, precise instruments like the Refracted Near-Field method are used to check if the final fiber’s profile meets the design targets. Any deviation will seriously affect the bandwidth.

Geometric Properties:

- Core Diameter: Must be 50 ± 2.5 µm or 62.5 ± 2.5 µm.

- Cladding Diameter: Must be 125.0 ± 1.0 µm.

- Core/Cladding Concentricity Error: The core must be as centered as possible within the cladding. Excessive eccentricity increases connection loss.

- These geometric parameters must be strictly controlled to ensure the fiber has low loss and high consistency during subsequent splicing and connection.

Attenuation / Loss:

- Measures the loss of the optical signal at specific wavelengths (e.g., 850 nm and 1300 nm) in units of dB/km. All OM-grade fibers have strict upper limits for attenuation (e.g., OM3/4/5 typically require ≤ 3.0 dB/km at 850 nm).

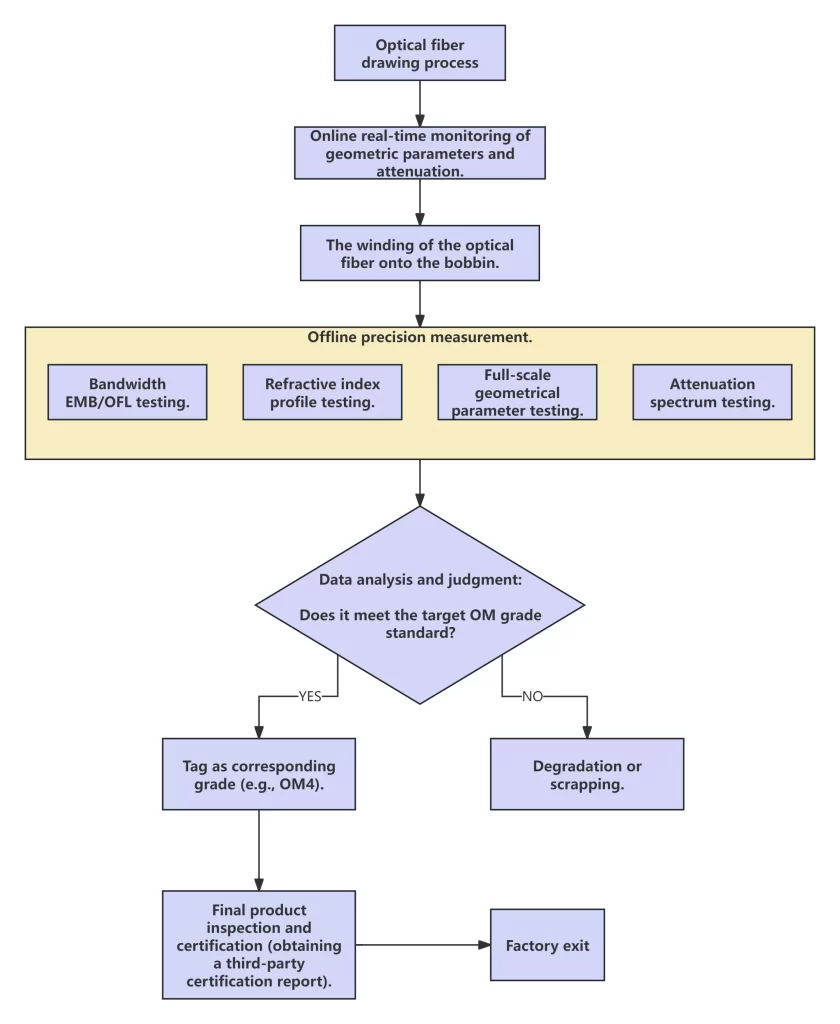

2. The specific process of optical fiber grading.

The entire process combines online monitoring and offline sampling.

Online Monitoring (During Drawing):

- During the drawing process, a laser micrometer provides real-time, non-contact monitoring of the fiber’s outer diameter. A feedback system then controls the drawing speed to ensure the diameter remains a constant 125 µm.

- An online attenuation monitoring system measures the fiber’s attenuation in real-time, allowing for the timely detection of any loss spikes caused by dust or preform defects.

Offline Sampling (Off-line Testing): This is the final step in the grading process. A sample is cut from a complete length of drawn fiber (which can be several kilometers long, up to ten or more). For example, a section might be taken from every 2 km of fiber.

- These samples are sent to a precision lab for comprehensive, rigorous testing using specialized equipment (such as a Vector Network Analyzer for bandwidth, or a Refracted Near-Field Analyzer for the profile).

- The most crucial measurement is the EMB value. Only if the measured EMB value meets or exceeds the OM4 standard (4700 MHz·km) can the fiber be labeled as OM4.

Data Analysis & Grading Decisions:

- Engineers analyze all the test data.

- Meeting the Target Grade: If all parameters (especially bandwidth, geometric dimensions, and attenuation) meet the standard for the target OM grade (e.g., aiming to produce OM4), the entire fiber length is certified as that grade.

- Downgrading: If the bandwidth (EMB) value is below the OM4 standard but above the OM3 standard (2000 MHz·km), that batch of fiber will be downgraded and sold as OM3. This ensures the integrity and reliability of the OM4 product. If the fiber doesn’t even meet the OM3 standard, it may be scrapped or designated for a lower-grade application.

Certification & Shipping:

- Each spool of fiber that is shipped out includes a test report detailing the measured values of its key parameters and certifying its OM grade.

- Major manufacturers also seek third-party certification (e.g., from UL or DELTA) to provide an authoritative “seal of approval,” such as a “UL Verified OM4” label.

3.Summary

In conclusion, the grading of multimode optical fiber after the drawing process is not a simple physical sorting task but a quality certification process based on precise optical measurements.

- Core Criterion: Effective Modal Bandwidth (EMB) is the most critical “report card” and directly determines whether the fiber is OM3, OM4, or OM5.

- Control Foundation: Precise refractive index profiling and geometric dimension control are the prerequisites for achieving high bandwidth.

- Final Assurance: Rigorous sampling, testing, and data analysis ensure that every meter of fiber is “true to its name.”